How the Latest MEMS Inertial Modules Help Overcome Application Development Challenges

MEMS-based Inertial Measurement Unit (IMU) is defined as a system in a package. It consists of an accelerometer mechanical sensing element, a gyroscope mechanical sensing element, and an electronic circuitry (“the brain”) to convert the acceleration and angular velocity into a readable format. The MEMS IMUs have been under development for decades, and they have been used in certain niche markets. However, the implementation of these IMUs in a wide range of applications experienced a steep increase only when the MEMS technology reached the level of maturity that was able to deliver low-cost and small-size devices.

Although the performance of these IMUs has been satisfactory for not-so-demanding applications such as simple motion detection, step counting, and portrait/landscape, the emergence of sensor applications in portable, wearable, and Internet of Things (IoT) devices created an urgent need for further performance improvement and current consumption reduction. The latest generation of MEMS IMUs satisfies these needs.

In the following article, we will review the latest advances in MEMS IMUs and describe how they can help hardware and software engineers shorten their development time and overcome challenges they have been facing.

How do the modern IMUs meet the challenging requirements of emerging applications?

The emerging MEMS sensor-based applications have very demanding requirements. That means that modern IMUs must be as small as possible, consume as little power as possible, and offer high sensitivity, excellent accuracy, high resolution, and very low noise level. The figure below illustrates the structure of a modern IMU housed in a tiny 2.5 x 3 x 0.8 package.

Figure 1: A modern IMU structure (system in a package) Size: 2.5 x 3 x 0.86 mm, Package: LGA-14.

In addition to the above-mentioned requirements, the latest IMUs offer embedded algorithms to help engineers reduce their design and development time. Table 1 highlights the major parameters and features of a modern IMU.

Device interface

There are two interfaces (SPI and I2C) to provide designers more flexibility to read the sensor data. In addition, the IMU supports Optical Image Stabilization (OIS) and Electronic Image Stabilization (EIS) applications using both the gyroscope and the accelerometer. Therefore, there is also a dedicated auxiliary SPI interface to output OIS data.

Image stabilization: EIS and OIS

One of the major advances in MEMS IMUs is their performance that can be used for very challenging OIS and EIS applications. The figures 2a and 2b show the diagram of how the OIS connections work.

Figure 2a: OIS data are outputted via a dedication SPI interface.

In figure 2a, the device can output the OIS data via a dedicated SPI interface. It offers a dedicated configurable signal processing path for the OIS application. The User Interface (UI) signal processing path is completely independent from the OIS segment and is readable through the FIFO feature embedded in the device.

Figure 2b: OIS data sent to an application processor directly or through the embedded FIFO.

Figure 2b illustrates a second option available in the IMU. The sensor data for the OIS application can directly be sent to an Application Processor (AP) on the system board. It is also possible to store the data in the embedded FIFO and then read the entire dataset from the FIFO into the AP.

The IMU offers Low Noise to improve the accuracy in demanding applications

There are many applications that require sensor data with a very low level of noise. However, the following two applications are among the most popular ones and require an IMU with a very low noise level and a high degree of bias stability:

Augmented Reality (AR): AR has recently attracted a huge interest in portable devices because of the improvements in recent MEMS IMUs. AR is a feature that is implemented by the interaction of superimposed graphics, audio, and other sensing enhancements over a real-world environment that is displayed in real-time, making it interactive and manipulatable.

Indoor positioning: the MEMS IMUs play a major role in implementing indoor positioning in places where access to GPS data is reduced or not available to provide an accurate and reliable positioning. The Pedestrian Dead Reckoning (PDR), which is a major building block of the indoor positioning, relies primarily on sensors to provide accurate data to be able to calculate the new location and the orientation. The performance and accuracy of an IMU are critical to the accuracy of the PDR solution.

The latest IMU solves the problem by offering very low noise gyroscopes and accelerometer. Table 1 above depicts the low noise levels for both the accelerometer and the gyroscope.

Embedded algorithms to help reduce design and development time

The embedded features in the MEMS IMU eliminate the need for code development for some applications. These features release SW engineers from writing codes for the embedded applications, which helps reduce the application development cycle. For example, a pedometer application would require the hardware and software engineers to spend months if not years to develop codes and perform tests. However, using a MEMS IMU with an embedded pedometer algorithm reduces these efforts significantly, and the engineers would only need to configure the pedometer application-related parameters in the device registers.

A modern MEMS IMU has been designed to be fully compliant with Android and features the following on-chip functions:

Event-detection interrupts (fully configurable)

The IMU offers event detection interrupts to help engineers implement a number of applications without any code development. The embedded event detection interrupts are the following:

Free-fall: uses the accelerometer data only. If the acceleration on all three axes falls below the preset thresholds, the interrupt is generated.

Wake-up: when the acceleration on at least one axis exceeds the preset threshold, the interrupt is generated.

6D and 4D orientation detection: uses the accelerometer data only and has the capability to detect the orientation of the device in the space, enabling an easy implementation of an energy saving procedure and automatic image rotation for handheld devices. The interrupt is generated when the device switches from one orientation to a different one. To recognize an orientation change, the following conditions need to be satisfied:

One axis is above the threshold and two axes are below the threshold (known zone).

The known zone is different from the previous one.

The threshold values can be configured via the dedicated registers embedded in the IMU.

Single and double tap: the device can be configured to output an interrupt signal on a dedicated pin when tapped (once or twice) in any direction. The threshold values and the time between the two events for double-tap recognition can be configured by the developer. The suggested Output Data Rates (ODRs) for tap and double-tap function are 400 Hz and 800 Hz.

Wake to sleep: the change of the state recognition ACTIVE/SLEEP (also known as activity/inactivity). After the user has set an ODR, if the acceleration data on all three axes are below a specified threshold for a specified duration of time, the device goes into Wake-to-Sleep mode (device @ lowest ODR 12 Hz). If the device is in sleep (inactivity) mode and the acceleration on at least one of the axes exceeds the threshold, the device then goes into Sleep-to-Wake mode (also called Wake-Up).

All these functions are in parallel and work correctly at an ODR lower than 1600 Hz. Each event can generate an interrupt signal that can be driven to the two interrupt pins of the device (INT1 and INT2).

Specific IP blocks with negligible power consumption and high-performance

To further reduce the total current consumption of the system and save developers significant development time, the new IMUs have some embedded IP blocks. The following two functions are among the ones widely used:

Pedometer functions: step detector and step counters: The embedded pedometer uses only the accelerometer data. It generates an interrupt when a step is detected. It counts the step events, and a maximum of 65535 steps (16-bit) can be stored. The reset of the steps number and algorithm reset are independent. The minimum threshold and the operating full-scale range are configurable.

Tilt: The tilt function has been implemented in hardware using only the accelerometer data to achieve both the targets of ultra-low power consumption and robustness. It is based on a trigger of an event each time the tilt of the device changes. For a more customized user experience, the tilt function is configurable through:

The programmable average window/duration of the event.

The programmable angle threshold that generates interrupt event (default 35°).

This event generates an interrupt when the tilt of the device changes by at least 35 degrees after its activation for at least two seconds. The tilt function can be used in different scenarios. For example, the interrupt is triggered when a phone is in a pocket and the bearer of the phone goes from sitting to standing or standing to sitting. However, the interrupt is not triggered when the phone is in a pocket while someone is walking, running, or climbing stairs.

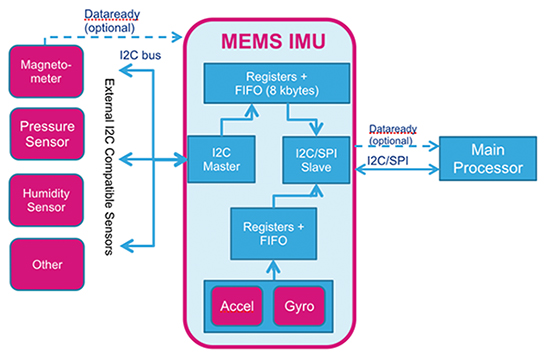

IMU as a sensor hub

One of the major advantages of the latest IMUs is the embedded sensor hub capability. The IMU offers hardware flexibility to connect the pins with different mode connections to external sensors to expand the functionalities of the IMU. The sensor hub enables the use of up to six sensors: two internal sensors (accelerometer and gyroscope) and four external sensors. The block diagram below illustrates the IMU as a sensor hub. The IMU offers a master I2C configuration to connect to external sensors and collect data. The collected data of the two internal sensors can simultaneously be stored in the embedded FIFO. There are two options available to trigger the master I2C to collect the data from external sensors:

Synchronous with the internal data-ready signal (XL or Gyro).

Synchronous with an external signal from one of the sensors (dedicated PAD).

The advantages of this sensor hub feature are data coherency, data synchronization, easier placement and routing, and lower overall system power consumption.

Figure 3: A MEMS IMU can be used as a sensor hub for sending data for multiple sensors to a central processor.

Conclusion

The latest MEMS-based IMUs offer significant improvements and help system designers and application developers to considerably reduce their design and development time. The price of such IMUs has dropped significantly while their performance and embedded features have improved greatly. The new IMUs have enabled hardware and software engineers to come up with new application ideas. The next generation of MEMS IMUs will continue to offer additional features and improved performance to meet the growing expectations of system engineers and application developers.

Comment